08, 2019

by Oree Laser

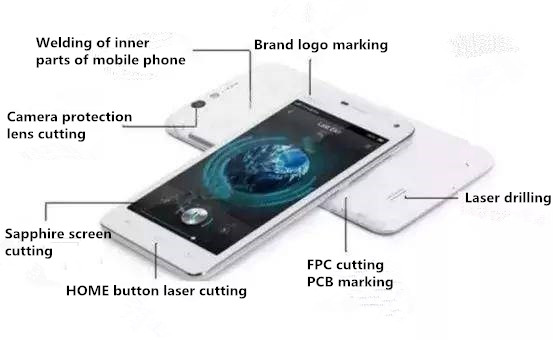

Laser has become a part of our life , and it is inextricably linked to our life. A mobile phone, everyone carries communication tools.How much does it relate to the laser? In the process of mobile phone manufacturing, laser equipment is used for brand LOGO marking, welding of mobile phone internal components and cutting of some mobile phone parts.

1.Laser marking: Every mark on the mobile phone is done by laser equipment.

Laser marking is a marking method that uses a high-energy-density laser to locally illuminate a workpiece, causing a chemical reaction of the surface material to vaporize or undergo a color change, thereby leaving a permanent mark. It has the characteristics of high precision, fast speed and clear marking. The mobile phone uses laser marking, which is a permanent marking method. It can improve the anti-counterfeiting ability and increase the added value, so that the product looks higher grade and more brand-like.

The laser marking technology is very mature. And it is widely used because of its low price, fast processing speed and good marking quality. In the field of mobile phones, it is mainly used for surface LOGO marks, text marks; internal electronic components and circuit board logos, text marks, and so on.

2.Laser cutting: hard, ultra-thin material, all done by laser.

Laser cutting can be used for precision cutting or micro-hole machining of small workpieces such as metal or non-metal parts. It has the advantages of high cutting precision, fast speed and small thermal influence. Common laser cutting processes on mobile phones include: sapphire screen cutting, camera protection lens cutting, mobile phone home button laser cutting, FPC flexible circuit board laser cutting, mobile phone handset laser drilling and so on.

3.Laser welding:The welding of mobile phone parts can only be done by lasers

Laser welding uses a high-energy-density laser beam as a heat source to melt and solidify the surface of the material into a whole. The size of the heat affected zone, the aesthetics of the weld, the welding efficiency, etc. are important indicators for judging the quality of the welding process. Compared with traditional welding, laser welding has many advantages such as small thermal deformation, high efficiency and good precision. Only the current price is relatively expensive and the penetration rate is low. The internal structure of the mobile phone is fine, and the welding spot area is required to be small. Ordinary welding is difficult to meet this requirement, so the welding between the main components in the mobile phone is mostly laser welding.

Professional Laser Cutting Machine Manufacturer - OreeLaser