10, 2018

by Ada.liu

Now, the laser industry develop rapidly, the fiber laser cutting machine is becoming the first choice and replacing the traditional cutting process with its advantages like good cutting quality and cutting efficiency, and no pollution, no consumables during the metal cutting process. However, there still have big difference in cutting quality and efficiency among the fiber laser cutting machine with the distinct components. Oreelaser as the professional laser manufacturer will show the most important six components for you when you want to purchase a fiber laser cutting machine that suitable for your condition.

STEP1. FIBER LASER

The fiber laser is belong to the high precision equipment, and the core motivation source of the fiber laser cutting machine. It is also the most expensive part of the fiber laser cutting machine. We must pay more attention to it when we purchase a fiber laser cutter.

The laser adopted by the fiber laser cutting machine is mainly fiber laser. At present, there are popular laser brand like Germany IPG and ROFIN, SPI in England in the international laser market, and domestic brand including Raycus and Max with high value is becoming

Popular. We all know that the imported laser with the characters like high purchase cost, long lead time but with the good cutting quality and efficiency, low maintenance cost and long service life. Compared with the imported laser, there are more choice in domestic market with lower price. Therefore, it is the best for us to meet our production requirement to choose the laser whether the imported or domestic brand.

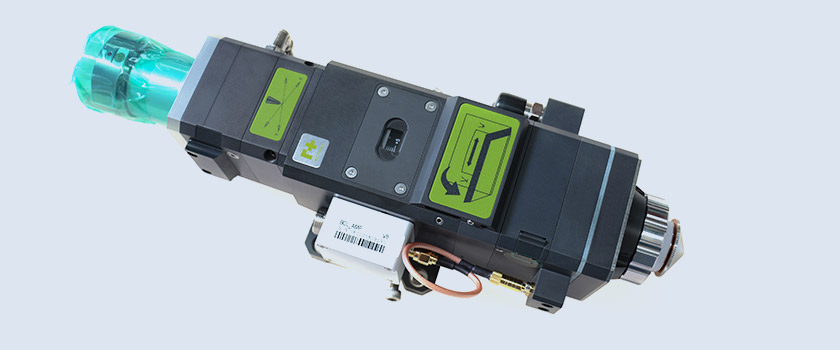

STEP2. Laser head

The laser cutting technology adopts a cutting head to focus the laser light emitted by the laser into a high-power density laser to cut the workpiece. The laser head is a laser output core device, which is composed of a focusing mirror, a focusing lens, a nozzle, a sensor, and a control system. Among them, one of the key factors affecting the cutting efficiency is the shape of the nozzle in the cutting head and the characteristics of the flow field generated. Reasonable auxiliary gas types and flow fields not only improve the processing capacity, but also limit the heat affected zone to a small range to ensure the processing quality.

In the laser cutting process, the distance between the cutting head and the workpiece is an extremely important factor, which directly affects the cutting quality. During the cutting process, to avoid collision between the cutting head and the protrusion of the workpiece, causing damage to the nozzle, cutting head or workpiece, a special sensor must be installed on the cutting head to automatically detect the change of the distance and automatically adjust accordingly. Therefore, the distance between the cutting head and the workpiece is kept constant, thus ensuring stable cutting quality and increasing process safety.

For different materials, the cutting head needs to be adjusted. A good cutting head can effectively improve the cutting effect and cutting speed. Inferior cutting heads can't even be cut on certain materials. Therefore, we have to choose the right laser head and adjust the laser cutting head height according to different materials to meet the laser processing needs.

STEP3. CNC system

The control system is the dominant operating system of the fiber laser cutting machine, which mainly controls the machine tool to realize the movement of the X, Y and Z axes, and also controls the output power of the laser. Its quality determines the stability of the operation performance of the fiber laser cutting machine. Through the precise control of the software, the accuracy and cutting effect can be effectively improved. At present, there Bochu system numerical control system, the PIC system numerical control system, and the PA8000 system are commonly used.

PIC system, which belongs to the older board control system, can be integrated into the ordinary computer to run, and uses the background software to control the analog signal transmission. Although the control system is old, it belongs to the complete Kaiyuan system.

Bochu system is a laser cutting machine system developed by domestic personnel for the domestic market. It is a non-closed-loop opening element system developed for laser cutting machines below 2000W. It has the many advantages like the simple operation and rich functions in the use of laser cutting machine within 1000W, are widely used by most domestic laser cutting machine manufacturers in laser cutting machines of less than 1000W. After years of upgrading and experimentation, it is currently a stable system configuration of laser cutting machines within 1000W.

PA8000 system, PA system is an open CNC system (CNC) based on PC technology. Open CNC technology represents the cutting-edge technology in the field of CNC in the world. Its advanced technology has been adopted by many famous automation companies all over the world.

STEP4. Motor

The motor of laser cutting machine is the core component of the motion system. The performance of the motor directly affects the processing effect and production efficiency. At present, the common motor includes two types of stepping motor and servo motor. When purchasing, we need configure the most suitable motor according to the industry of the processing object.

1.fiber laser cutting machineStepper motor has a great influence on the precision of laser cutting. The starting speed is fast and the reaction is sensitive. It is suitable for engraving and cutting processing. Stepper motors have many brands and different performances, so a good stepper motor is very necessary.

2.Servo motor is a very important component in laser cutting machine. Its quality directly determines the stability of equipment use. High-quality servo motor can effectively ensure cutting accuracy, positioning speed and repeatability. At present, there are some servo motor brands used widely in the manufacture of laser cutting machines like Mitsubishi, Fuji, Yaskawa, Panasonic and Delta.

For the laser cutting machine, the key is to process the equipment according to the established graphics whether for plate cutting or pipe cutting. The motor as an intermediate actuator for mechanical and control systems, which can compensate, optimize and coordinate the actions of the various systems to achieve a more perfect control. Therefore, motors are also the most important concern when purchasing machines.

STEP5. Bed Frame

The stability and durability of the fiber laser cutting machine body structure is very important. The requirement of the machine tool stability is very high, because the high precision and high stability machine tool is beneficial to improve the precision of laser cutting. It directly affects the cutting precision, efficiency and life of the equipment. Therefore, the customers pay special attention to the structure and material technology of the bed when purchasing fiber laser cutting machine. The current advanced bed technology in the industry is a heavy cast iron bed, because of it has the comprehensive properties such as wear resistance, corrosion resistance and shock absorption. And the stress deformation effect is much lower than that of welded components after heat treatment. Its shock absorption performance is especially suitable for users who install machine tools with large running vibrations in the workshop.

STEP6. Laser lens

Laser lenses are the most used in the entire fiber laser cutting equipment. Many optical devices contain laser lenses. Different lenses have different functions, such as full-reflex lenses, semi-reverse lenses, and focusing lenses. The quality of the lens directly affects the output power of the laser, which also affects the performance of the whole machine. If the lens is not properly selected, it will cause large laser loss, frequent damage to the protective lens, and unstable product quality, causing serious losses to the enterprise. Therefore, choosing the right protective lens is a very important thing to pay attention to. There are three steps to choose the laser lens of the laser cutting machine:

1. The dimensions are matched.

2. You can choose K9 or quartz material, according to different laser and considering the cost of use. During the actual application process, professional manufacturers divide the two types of materials into multiple grades, customers can choose the corresponding specifications according to actual needs.

3. Coating, choose different coating technical parameters according to the use of the environment.

Although the laser lens of the laser cutting machine is a wearing part, in order to improve its utilization rate and reduce the production cost, the lens can be cleaned by timing to achieve the purpose of recycling.

Professional Laser Cutting Machine Manufacturer - OreeLaser