03, 2019

by oreelaser

With the strengthening of safety awareness, the people pay more attention to the safety of drugs. When there is a problem with the drug, the source of direct traceability is the identification code on the package of the drug. Therefore, the importance of drug labeling can be seen. And the pharmaceutical packaging industry needs to strictly control the drug labeling process. Today we will learn about the specific application of fiber laser marking machine in the drug labeling.

The medical drug label generally contains the batch number, serial number and other identification information. In the past, the drug label was a label attached to the bottle. Many counterfeit products were directly torn off the label on the bottle and re-applied with a new label, or wiped the ink mark. Therefore, there will be many the hidden dangers. With the development of scientific and technological information and the medical industry, the establishment of a complete drug traceability system has been increasingly valued by the public and pharmaceutical manufacturers.

Fiber laser marking machine

Fiber laser marking machine is adopting a laser beam to mark permanent surfaces on a variety of different materials. The effect of marking is to expose deep substances by evaporation of surface substances, or to engrave traces by chemical or physical changes of surface substances caused by light energy, or to burn off some substances by light energy to show the desired etching pattern and text. The laser marking machine can accurately print the corresponding supervision code in the medicine packaging box, which has the characteristics of non-contact, no pollution and high processing precision. Besides that it is more flexible to print digital, text and graphics, and the number of lines and font size printed is unlimited, and users can easily set them as needed.

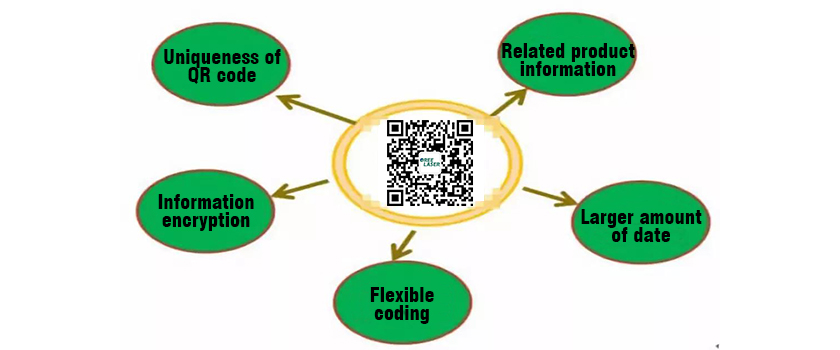

With the continuous development of the "Internet +" and laser marking technology, more and more enterprises and custmers have adopted Internet thinking, combine the Internet with laser marking to develop new laser application fields and establish product anti-counterfeiting traceability information and intelligent systems. Laser marking technology can realize internal quality control and external customer terminal inquiry by laser marking irreversible two-dimensional code, chip laser marking, etc. This application has been widely used in food, medical, electronic products, industrial parts and other industries, while laser anti-counterfeiting traceability technology is consistent with relevant national laws and regulations, and can realize the safety and anti-counterfeit traceability of any product quickly and comprehensively.

Professional Laser Cutting Machine Manufacturer - OreeLaser