02, 2020

by Oree Laser

Water chillerprotection before the festival

Be sure to drain the cooling water of the laser and water cooler cleanly to prevent the cooling water from icing and damaging the equipment during shutdown. Even the antifreeze must be drained clean, because most of the antifreeze contains corrosive components. It is not recommended to be stored in the device for a long time;

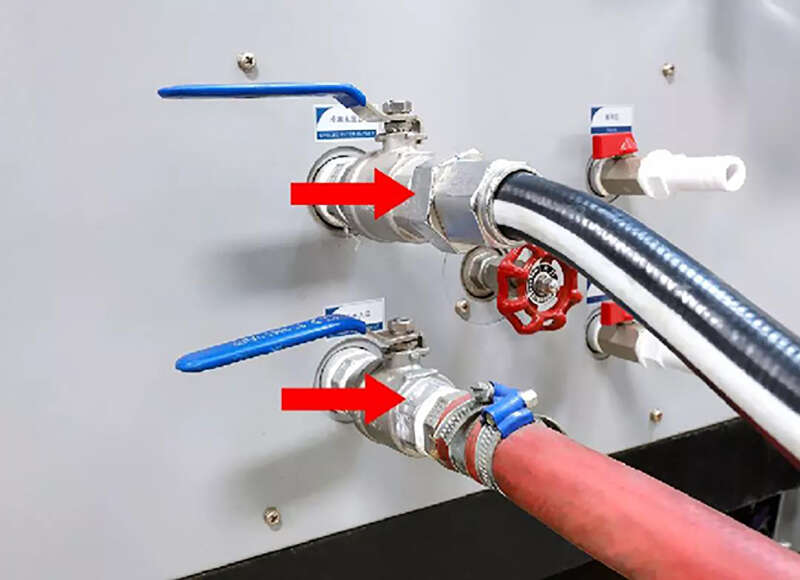

Water cooler drainage method: Remove the water pipe of the water inlet from the water cooler, and then use compressed gas to vent the water inlet until the residual water in thewater cooler is blown out.

▲Water cooler drainage example diagram

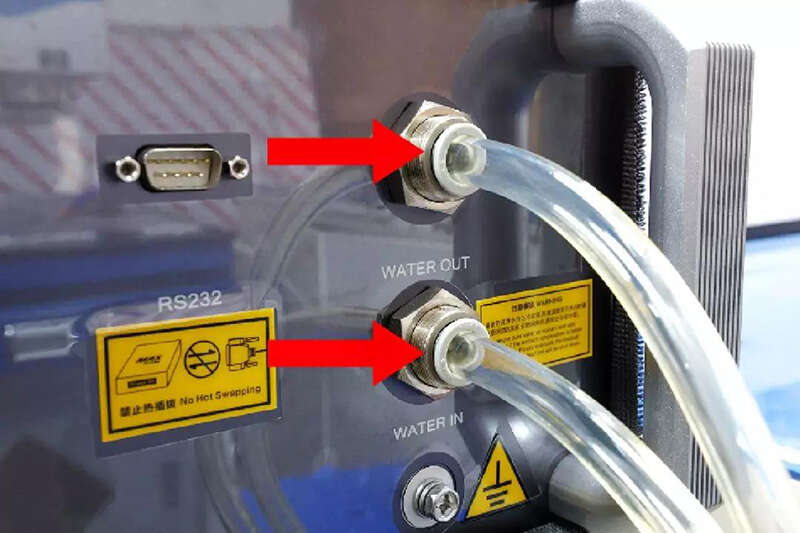

Multi-mode laser drainage method: Remove the water pipe at the water inlet from the laser, and then use compressed gas to vent the water inlet until the residual water in the water cooling pipe inside the laser is blown out from the water outlet.

▲Example diagram of multi-mode laser drainage

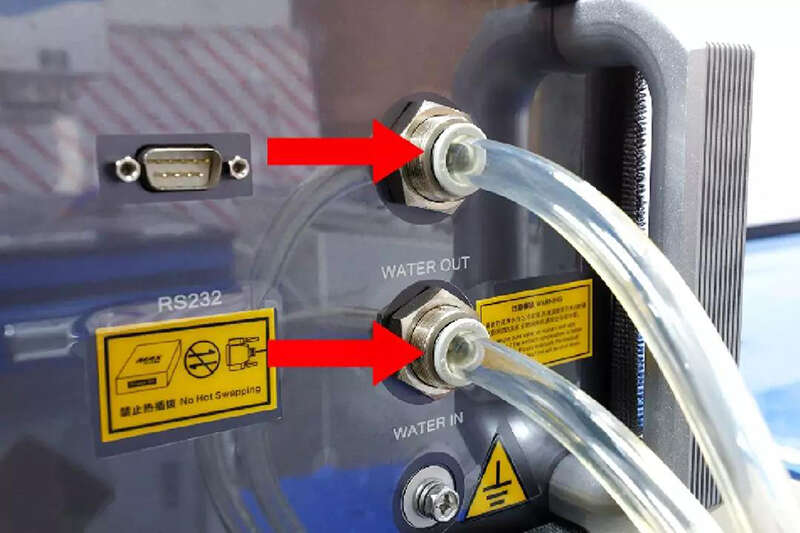

Single-mode laser drainage method: Remove the water pipe at the water inlet from the laser, and then use compressed gas to vent the water inlet until the residual water in the water cooling pipe inside the laser is blown out from the water outlet. Then plug the water inlet and outlet with a water pipe (or rubber plug) to prevent dust from entering the water pipe.

▲Example diagram of single mode laser drainage

Disconnect power to the unit to prevent accidents when left unattended.

To ensure the safety of the equipment during the vacation period, the AC power of the laser needs to be disconnected to avoid the impact and damage to the laser caused by the unstable or abnormal fluctuation of the grid voltage when the plant is first powered on.

Steps:

1. The laser is turned off according to the correct operation steps: turn off the [Start button] → turn off the key switch → turn off the power → turn off the chiller (note: the water chiller is turned on first after the holiday);

2. Disconnect AC power:

❖If the laser is installed with a dedicated AC circuit breaker as required, please ensure that the circuit breaker is in the open state;

❖If there is no special circuit breaker, disconnect the AC power supply of the cutting machine, or directly disconnect the AC power line of the laser.

Water cooling machine restart mode

1. Fill the water cooler with the required amount of cooling water and reconnect the power line;

2. If during the holidays, the device is in an environment above 5 ° C, confirm that there is no freezing, the device can be directly adjusted to the boot state;

3. If the ambient temperature is below 5 ° C, leave it for a period of time after adding cooling water, or use a warm air device to blow the internal pipes of the water cooler for a period of time, confirm that there is no freezing, and then turn on the device;

4. Note that when the laser and water cooler are refilled with water for the first time, the flow may be low due to air in the pipe, and a water flow alarm will occur. If this happens, please exhaust the water cycle through the exhaust hole of the pump or restart the pump several times at 10-20 second intervals.

Professional Laser Cutting Machine Manufacturer - OreeLaser