10, 2019

by Oree Laser

The hygiene and safety of the drug itself is very important, but the package of the drug is also very important. Drugs are not equivalent to other commodities, drugs can only be developed, produced, distributed, and used through strict requirements and specifications. Drug labeling plays an important role in the construction of drug safety mechanisms. Information such as production date, production batch number, main components, the scope of application, and shelf life are important sources of anti-counterfeiting and traceability.

Laser marking machine is a method of marking a surface of pharmaceutical packaging material with a high-energy-density laser to vaporize the surface of the drug packaging material or chemically react with color changes, thereby leaving a permanent mark. Traditional ink printing techniques are volatile, easy to smear and tamper, making it possible for criminals to take advantage of it. Once the drug is circulated in society, it will endanger people’s health and it is difficult to trace its source. Oreelaser's fiber laser marking machine for sale has the characteristics of high-speed operation, artistic design, and high performance. This system support marking on stainless steel, carbon steel, alloy steel, spring steel, copper plate, aluminum plate, gold, silver, titanium, other products, painting acrylic, density board, plastic, acrylic acid, rubber, bamboo, marble, painting glass, TPU (Thermoplastic polyurethanes). The non-contact and non-contaminating marking method not only can satisfy the use of a variety of packaging materials, but also can not easily erase and tamper all the information marked on the packaging materials of the medicine, and has anti-counterfeiting property so that all the information of the medicines in circulation can be traced. As long as there is a problem in any link, you can use the relevant code to query the root cause of the problem.

For example, the capsule mark, the previous mark method of the medicine capsule we eat is ink printing, and the ink printing directly sprays the ink on the capsule. Although these inks are small, they are directly damaged to the human body. The laser marking machine can effectively avoid this defect and can engrave text and pictures on the medicine capsule, and successfully handle the ink contamination caused by the symbol of the medicine. Compared with traditional ink printing machine, laser marking machine does not require any consumables, and printed medicine has no toxic and side effects. It saves ink and other consumables costs for capsules and pharmaceutical manufacturers and effectively ensures the recording of drug information and anti-counterfeiting labels.

While the development of the Internet has brought convenience to people’s lives, it has also become an important technical means for drug safety traceability. The laser marking information is clear and intuitive, corrosion-resistant, not easy to tamper and erase, and it ensures the anti-counterfeiting performance of medical products. When laser technology encounters Internet plus, big data is an important technical support to improve drug safety, further ensuring the safety of drugs. With the drug label, information on the production, distribution, and use of drugs can be queried via Internet technology, and the deficiencies in the provision of public goods and services by the pharmaceutical distribution industry can be improved. For example, the quality and safety of circulation, the supply of rural and remote areas, the supply of low-cost drugs and small varieties, the storage of disaster prevention and epidemic emergency medical equipment, and improvement of pharmaceutical service capabilities. With the use of tracking technology, the application of laser marking is more and more extensive, and the market space is huge.

Medical packaging box

The laser marking on the box is a simple and clean way to identify text, barcodes or images without consumables.

Medicine bottle

Laser marking technology uses a small mirror or turbulence meter to direct the laser beam to directly engrave or ablate the ink surface on the plastic bottle label.

Flexible materials

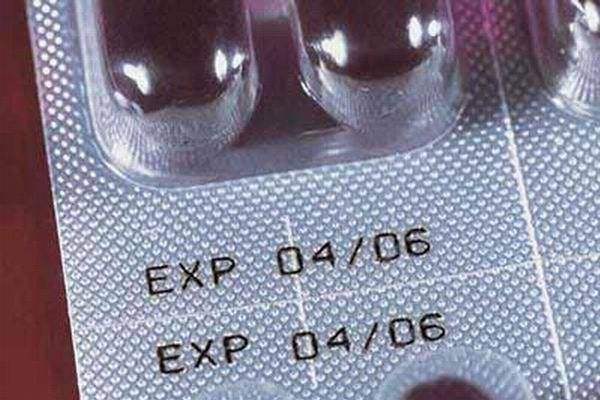

Laser marking machines can be used to mark various bubble cover materials. A properly specified and installed laser marking machine makes it easy to print high-quality code for multiple packaging lines.

Professional Laser Cutting Machine Manufacturer - OreeLaser