05, 2020

by Oree Laser

After more than ten years of development, the laser cutting machine has already replaced the traditional process and become the mainstream of sheet metal processing. At present, various laser cutting products can be seen everywhere in life.

Which industries need laser cutting? Laser cutting plays an important role in petroleum pipelines, automobile manufacturing, elevator manufacturing, aerospace, engineering machinery, shipbuilding, and precision medical and beauty equipment processing, home appliances and kitchen appliances, and fitness equipment manufacturing.

● Auto industry

As one of the most intelligent industries at present, automobile manufacturing has integrated a variety of production processes, and laser, as one of the most important technologies, has achieved up to 70% intelligent production of accessories. Many places in the automotive industry also need to use laser cutting machine technology, such as front cover, automobile sheet metal, etc.

● Sheet metal decoration industry

Because of its fast cutting speed, flexible cutting and precision machining, laser cutting machine is deeply loved by decoration companies. As long as it is required by the customer, after making the drawings through computer-aided design, the relevant materials can be directly cut out.

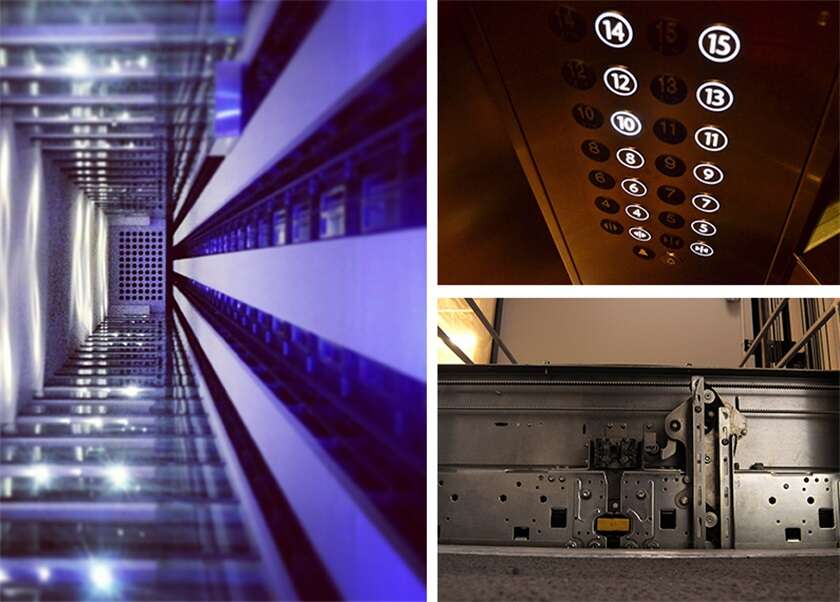

● Elevator manufacturing

With the tremendous changes in the residential market, the elevator market is developing faster and faster. For elevator sheet metal parts, laser cutting machine has the advantages of high precision and fast cutting speed.

● Kitchenware industry

With the development of society, the demand for kitchenware-related products is increasing. Laser cutting machine is very suitable for cutting thin stainless steel and can realize customized and personalized product development, which is deeply loved by kitchenware manufacturers.

● Aerospace

Laser manufacturing technology is an important part of the aerospace manufacturing field. Due to the high efficiency and high precision of laser processing, it is widely used in aircraft, aerospace rockets and other main bodies, components and spare parts.

● Construction machinery

At present, in the construction machinery industry, a large number of round holes, square holes and special-shaped holes need to be cut on plates of various thicknesses, and the precision requirements are very high. Using laser cutting and blanking can quickly pierce and cut out the ideal shape, which greatly improves production efficiency and product quality.

● Shipbuilding industry

Many large shipyards have generally adopted large-format thick sheet laser cutting machines. Some traditional processing plants are also gradually using laser cutting to replace the original flame cutting and plasma cutting.

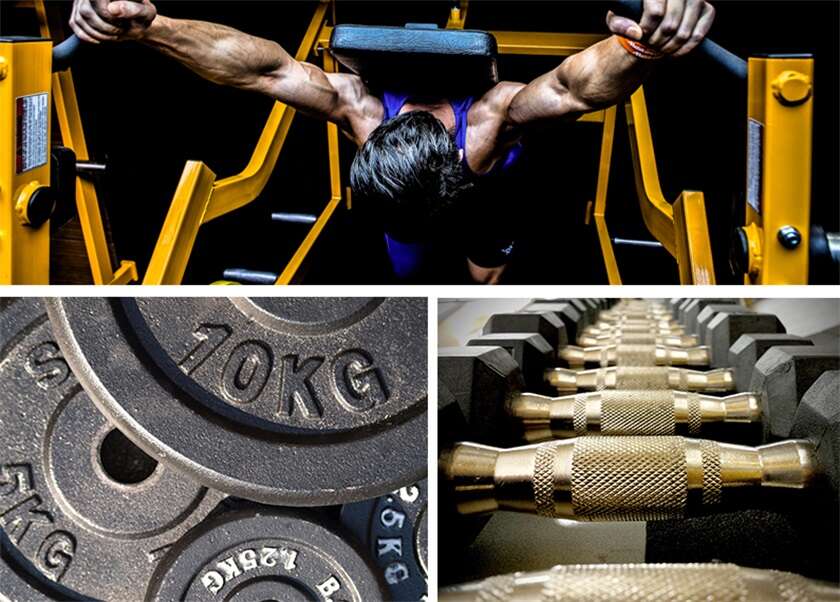

● Fitness Equipment

The fitness equipment industry has put forward higher requirements for the diversity of laser cutting. To cope with the market demand, many manufacturers have also produced laser cutting machines for both tubes and tubes, which greatly promoted the development of the fitness industry.

● Electric cabinet

The advanced application of metal laser cutting machine has saved more production costs for the mechanical electrical cabinet manufacturing industry and created a more efficient production cycle.

Oree laser focuses on the production of laser cutting machines, if you need to know more laser cutting machine products, please contact us, contact: +86 155 0869 2995, looking forward to your call.

Professional Laser Cutting Machine Manufacturer - OreeLaser