08, 2019

by Oree Laser

With the increasing power of fiber lasers, lasers have been widely used in cutting industry . As the core of the laser cutting machine, the laser is equivalent to the engine of the car, which has a great influence on the cutting effect . Due to its high beam quality, fiber lasers can achieve very small focal diameters. And the small slits are refreshing the process standards in all areas.

We have used laser cutting machine for so many years, do you really know its "engine"? The fiber lasers are divided into single mode and multiple mode. In the cutting application, what are the advantages of the single mode laser, and what are the differences between the single mode and the multiple mode ? Today OREE will be with you together to find the answer!

(1)The same power laser, many enterprises can do a single mode will be able to do multiple mode. On the contrary, that's uncertain.

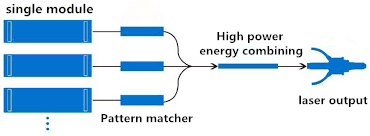

Why do you say that? In fact, multiple mode is a complex structure that is made up of two or more single mode. A 6000w multiple mode laser can be composed of six 1000w single mode lasers, and the same a 8000w multiple mode laser can be composed of two 4000W single mode lasers or four 2000w single mode lasers.

(2)High reliability.

The single mode laser has only one optical module and one electrical module.It has simple structure, strong stability and high reliability.The more modes, the more complex the lines, the higher the damage rate. OREE laser cutting machine, laser single mode maximum power is 4000w. We use multi-mode lasers with power above 4000w.To enable our machines to better serve our customers, we also recommend the use of higher power single module lasers.Because product quality is the most convincing!

(3) Convenient maintenance.

The multi-module structure is complex. And it is not easy to be repaired. The simpler the structure of the laser is, the easier it is to repair. For the customer, the maintenance cost can be effectively reduced, and the production profit can be improved. The service concept that OREE has been practicing is the "Every little thing about the customers is our big thing".

(4)When cutting high reflective materials, the cutting effect of single mode laser is better than that of multi-mode laser.

The fiber core diameter of single mode laser is fine, the spot is thin, and the aggregation energy is high. In the cutting of high reflective materials, the first is drilling. The faster the drilling, the smaller the reverse. Namely: improve the focusing ability, shorten the perforation time, improve the cutting stability.

(5) The medium and thin plates cut faster and have “overstep” performance.

A large number of experimental results show that the 4000w single-mode laser from OREE and the other 6000w multi-mode laser cut 6mm stainless steel at the same time, the cutting effect is almost the same.

(6)The cutting performance of thick plate is consistent with that of multi-mode: The single mode laser can achieve this performance by beam shaping and flat-top annular light output.

Generally, laser with good beam quality has more advantages in cutting thin plates, and single-mode laser has higher beam quality.Multi-mode laser is more suitable for cutting thick plate.Therefore, the laser used in OREE laser cutting machine has been innovated in technology-flat top annular light output, which weakens the focus energy accumulation and strengthens the aura energy.

Finally, I would like to ask you a question. As mentioned above, the 8000w multi-module laser can be composed of two 4000W single-module lasers or four 2000w single-module lasers. Which of these two lasers is more advantageous? You can leave your views in the comment area. The answer is in the next issue.

Would you like to know about OREE products? Please click on the website address below.

https://www.oreelaser.com/Product-Category.html

Professional Laser Cutting Machine Manufacturer - OreeLaser