11, 2018

by oree laser

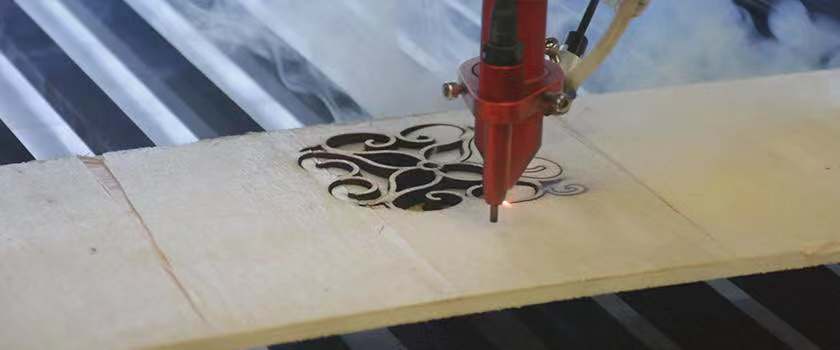

There are different requirements and technical methods for laser engraving machine to engrave different woods. Here are four points to introduce the technical points that laser engraving machine for wood.

1. Plywood

Sometimes customers may ask you to engrave on plywood. In fact, this is almost similar to carving on wood. There just a little attention to pay that the depth of engraving should not be too deep. The glued reverse edge after cutting by the laser engraving machine will also be black like wood. The key is to see which wood the plywood is made from.

2. Logs (raw wood)

Wood is the most commonly used laser processing material for the laser engraving machine and is easy to engrave and cut. Light-colored wood like birch, cherry or maple can be well vaporized by laser engravers, so it is more suitable for engraving. As we all know that each type of wood has its own characteristics, some of which are dense, such as hardwood, which requires the laser engraver with greater laser power for engraving or cutting. Therefore, it is recommended to study the engraving characteristics before carving wood that is not familiar enough.

3. Coloring

After wood be engraved by the laser engraver, there will generally be a feeling of being burned. Matching the color of the wood has an original artistic beauty. The depth of the color depends mainly on the laser power and the engraving speed of the laser engraving machine. But for some woods which are usually softer in texture, and no matter how to carve you can't change their color anyway like birch. Sometimes customers may ask you to color the finished product, you can use acrylic paint to realize what the customer want to engrave.

4. Wood cutting

The depth of laser engraving machine cutting wood is generally not deep, within 5mm, because the laser power of the laser engraving machine is small, if we cut with a slow speed will cause wood burning. For specific operations, try using large-size lenses and repeating them.

Professional Laser Cutting Machine Manufacturer - OreeLaser