08, 2018

by Site Editor

ou can find the normal solution about laser cutting machine and laser cutting process.

Working Principle

Laser cutting is a technology that uses a laser to cut materials, and is typically used for industrial manufacturing applications, but is also starting to be used by schools, small businesses, and hobbyists. Laser cutting works by directing the output of a high-power laser most commonly through optics. The laser optics and CNC (computer numerical control) are used to direct the material or the laser beam generated. A typical commercial laser for cutting materials would involve a motion control system to follow a CNC or G-code of the pattern to be cut onto the material. The focused laser beam is directed at the material, which then either melts, burns, vaporizes away, or is blown away by a jet of gas, leaving an edge with a high-quality surface finish. Industrial laser cutters are used to cut flat-sheet material as well as structural and piping materials.

Factors Influencing on the Dimensions Accuracy in Laser Cutting

We confirm a laser cutting machine manufacturer is excellent, the cutting precision is the first standard. Therefore, how to confirm the cutting precision whether qualified will be from the following four factors considered

1. the size of the laser coagulation of the laser generator. If the spot is very small, the cutting accuracy is very high, and if the gap is very small after cutting. It shows that the precision of laser cutting machine is very high, and the quality is very high.

2. the accuracy of the working table. If the accuracy of the working table is very high, then the accuracy of the cutting will be improved. Therefore, the precision of the working table is also a very important factor to measure the accuracy of the laser generator.

3. laser beam condensed into a cone. When cutting, the laser beam is to taper down, when the thickness of the workpiece cutting is very large, cutting accuracy will be reduced, cut out the gap will be very large.

4. cutting the material is different, also will affect the precision of the laser cutting machine. In the same case, the cutting of stainless steel and aluminum will be very different accuracy, stainless steel cutting accuracy will be higher, and the section will be smooth.

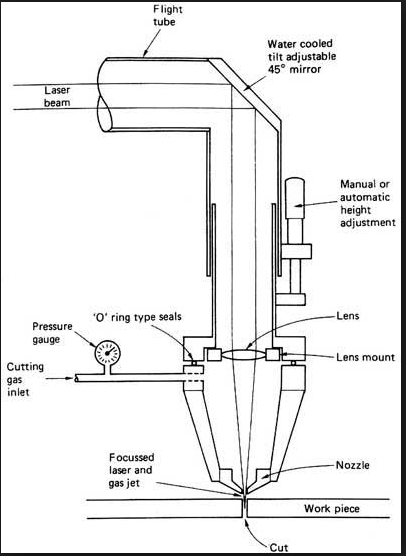

How to focus the laser

The laser beam is focused through the focal lens. The focal lens acts like a magnifying glass and sunlight. For a 55mm lens, the laser beam passes through the lens and converges to the smallest point at about 55mm from the edge of the lens. The laser beam is concentrated to the smallest size at this "spot". Given that the lens is mounted in the focal tube, the question is how to put the material at the optimum location to engrave or cut.

First, think of what results are desired. Whenever we want to engrave, we want to have the laser beam focused to the smallest spot and that spot located at the top surface of the material. Having the smallest spot size will give us the best resolution. the best DPI (dots per inch). The laser machine should have come with a manual height measurement tool. Some machine come with a square piece or acrylic to match to a marker on the side of the focal tube. Other machines come with a feeler gauge that snuggly fits between the focal tube nozzle and the top surface of the material.

The normal adjustment method is to place the material on the worktable and then to move the worktable height such that the top surface of the material is at the focus spot of the laser beam. Use the measurement tool while moving the table to the proper height. Make sure not to move the table too far. You will not want to damage the table surface, material, or the focal assembly.

Most laser machines have a movable table height. If the table will not move or is already moved to the top, then the focal tube has some adjustment to move/slide up and down about 1.5 inches. First, loosen the focal tube nut (or screw). Second, move the focal tube to the desired height above the material surface. Last, tighten the focal tube nut (or screw).

You may be concerned that you are using the provided tool to place the focus at the prescribed distance, but the focus just doesn't seem right. Please remember that the Chinese optics are not the best. The optimum focal distance might be slightly closer or farther away from the lens. Place a piece of flat scrap material (wood) under the focal assembly. Adjust the focus such that the material is slightly too close to the focal lens. Use the "laser" button to make a test spot on the wood. The spot size will be larger than desire for engraving. Move the table away from the lens just a small distance. Move the wood to a clean target location. Make another test spot using the "laser" button. The spot size should have gotten smaller. Continue moving the table and making test spots on the wood surface. When the spot starts getting bigger, then you have just passed the focal point. This is the easiest way to find the true focal distance of your lens.

To get the best engraving....

1. Make sure that your laser is focused on the material.

2. If your target material is an uneven surface, then it may find some areas where the laser is out of focus.

3. If your target material is a dowel rod and you are not using a rotary attachment. The laser will be out of focus at some portions of the image.

4. If your image seems fuzzy at the edges of the laser cut, but is focused, then you might be trying to engrave at too high of a speed. Set the engraving speed to a slower rate. You will also need to reduce the laser power percentage as to not over-burn the material.

5. If your material shows (Scan) lines in the engraved areas, then the "scan gap" may need to be reduced. The "scan gap" is the amount of space that the rail moves in the Y direction between engraver scanning passes. Setting the "scan gap" to a lower number will give a better resolution. With some materials (anodized aluminum, hard plastics, and hard wood), a scan gap of 0.05 may give excellent results. A good setting for glass is 0.07. In soft plastics, a scan gap of 0.1 will be needed to ensure the plastic does not glob. A setting of 0.1 is good for soft woods.

If you are regularly engraving materials that vary in distance from the focal point, then it may be a good idea to purchase a focal lens with longer focal length. The longer focal length will stay tighter to focus for more distance.

Types

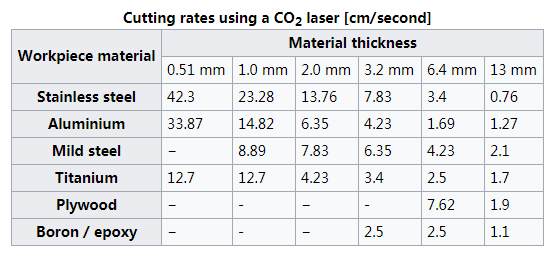

There are three main types of lasers used in laser cutting. The CO2 laser is suited for cutting, boring, and engraving. The neodymium (ND) and neodymium yttrium-aluminum-garnet (ND-YAG) lasers are identical in style and differ only in application. ND is used for boring and where high energy but low repetition are required. The ND-YAG laser is used where very high power is needed and for boring and engraving. Both CO2 and ND/ ND-YAG lasers can be used for welding.

Common variants of CO2 lasers include fast axial flow, slow axial flow, transverse flow, and slab.

CO2 lasers are commonly "pumped" by passing a current through the gas mix (DC-excited) or using radio frequency energy (RF-excited). The RF method is newer and has become more popular. Since DC designs require electrodes inside the cavity, they can encounter electrode erosion and plating of electrode material on glassware and optics. Since RF resonators have external electrodes they are not prone to those problems.

CO2 lasers are used for industrial cutting of many materials including mild steel, aluminum, stainless steel, titanium, task board, paper, wax, plastics, wood, and fabrics. YAG lasers are primarily used for cutting and scribing metals and ceramics.

In addition to the power source, the type of gas flow can affect performance as well. In a fast axial flow resonator, the mixture of carbon dioxide, helium and nitrogen is circulated at high velocity by a turbine or blower. Transverse flow lasers circulate the gas mix at a lower velocity, requiring a simpler blower. Slab or diffusion cooled resonators have a static gas field that requires no pressurization or glassware, leading to savings on replacement turbines and glassware.

The laser generator and external optics (including the focus lens) require cooling. Depending on system size and configuration, waste heat may be transferred by a coolant or directly to air. Water is a commonly used coolant, usually circulated through a chiller or heat transfer system.

A laser microjet is a water-jet guided laser in which a pulsed laser beam is coupled into a low-pressure water jet. This is used to perform laser cutting functions while using the water jet to guide the laser beam, much like an optical fiber, through total internal reflection. The advantages of this are that the water also removes debris and cools the material. Additional advantages over traditional "dry" laser cutting are high dicing speeds, parallel kerf, and omnidirectional cutting.

Fiber lasers are a type of solid state laser that is rapidly growing within the metal cutting industry. Unlike CO2, Fiber technology utilizes a solid gain medium, as opposed to a gas or liquid. The “seed laser” produces the laser beam and is then amplified within a glass fiber. With a wavelength of only 1.064 micrometers fiber lasers produce an extremely small spot size (up to 100 times smaller compared to the CO2) making it ideal for cutting reflective metal material. This is one of the main advantages of Fiber compared to CO2

Production and cutting rates

Application

Laser cutting and laser fine cutting are applied for different kinds of materials where complex contours demand precise, fast and force-free processing. Lasers create narrow kerfs and thus achieve high-precision cuts. This method does not show any distortion and in many cases post-processing is not necessary as the component is subject to only little heat input and can mostly be cut dross-free.

Almost all kinds of metals can be laser cut: mild steel, stainless steel and aluminum are the most common applications. Other laser cut parts are made from wood, plastics, glass and ceramics. Compared to alternative techniques like die cutting, laser cutting is cost-efficient already for small-batch production. The big benefit of laser cutting is the localized laser energy input providing small focal diameters, small kerf widths, high feed rate and minimal heat input.

Mild steel

The cutting in two dimensions is a domain of the CO2 laser. Typical cutting speeds for mild steel are for example at 18m/min for 1 mm, 4.5 m/min for 3 mm and 1.5 m/min for 8 mm material strength. Basically, the cutting of metals with lasers happens through the local heating of the material above its melting point in the focal point of the focused laser. The resulting molten material is ejected by a gas flow oriented coaxially to the laser beam so that a kerf is formed.

For low-alloyed steels in particular, oxygen is typically used as cutting gas. At the moment, the maximal processable counter thickness for laser flame cutting of steel is approximately at 25 mm.

Stainless Steel

Stainless steel is processed with laser fusion cutting. CO2 and also solid-state lasers are suited for this kind of applications, with CO2 lasers being preferred for cutting of thicker materials. CO2 lasers cut stainless steel and construction steel at a cutting speed of 18m/min at a material strength of 1 mm.

In micro material processing solid-state lasers (fiber laser, pulsed ND: YAG) are commonly applied for laser cutting stainless steel, providing cut widths down to 20 microns depending on the steel thickness.

Non-Ferrous Heavy Metal (Processing of Highly Reflective Materials)

Aluminum, magnesium, brass, copper, bronze, titanium, zirconium, nickel, silver, gold, platinum, tantalum, zinc or tin are examples for non-ferrous metals that can be cut with a laser.

Depending on the requirements of the workpiece and material thickness, you can use either removal cutting processes with pulsed lasers or fusion cutting processes with CW lasers.

Micro or Macro?

Thin workpieces can be cut with either pulsed lasers or continuous wave lasers. With these processes, an assist gas is used to expel molten material out of the kerf, resulting in a burr-free cutting edge. The width of the kerf will be between 50-300 micrometer depending on the material and the type of laser. The laser power determines the cutting speed, which can range from 0.5m/min to over 100m/min. Using these cutting processes on thin material, pulsed lasers achieve high accuracy, high quality, and the thermal impact is low. Continuous wave lasers (macro) using the same process will be able to achieve very high cutting speeds.

Sublimation cutting is done without any cutting gas. The material evaporates directly, and the kerf is created by gradual ablation. This can be realized using single mode fiber lasers (macro) or by short pulse lasers with high peak power (micro). With both processes, mirror deflection systems are the preferred option for the beam movement.

Macro: which is the right laser?

Both CO2 and fiber lasers can be used for cutting the most non-ferrous metals. Some non-ferrous metals reflect the CO2 laser beam so strongly that fiber laser cutting is preferred. This applies for copper (cu), gold (au) and silver (ag). For all other non-ferrous metals, you can say: fiber lasers mainly have their advantages in thin sheet, but CO2 lasers mostly have a better quality for thicker material.

Noble Metals

Perfect Cutting Results for Metals with High Heat Conductivity Precious metals, like gold, silver and platinum metals can be laser cut. Platinum metals are cut by the CO2 laser as well as solid-state lasers, whereas for gold and silver, pulsed or q-switched YAG lasers are the tool of first choice as wavelengths of solid-state lasers are better absorbed.

Professional Laser Cutting Machine Manufacturer - OreeLaser