02, 2021

by oreelaser

In order to ensure the normal operation and good processing quality of laser cutting equipment, relevant inspection work must be done before equipment work. Today we mainly share the inspection items before the use of the 10kw+ laser cutting machine

02, 2020

by Oree Laser

Is there a big difference between a cast iron bed and a welded bed, and what should customers choose?

07, 2019

by Oree Laser

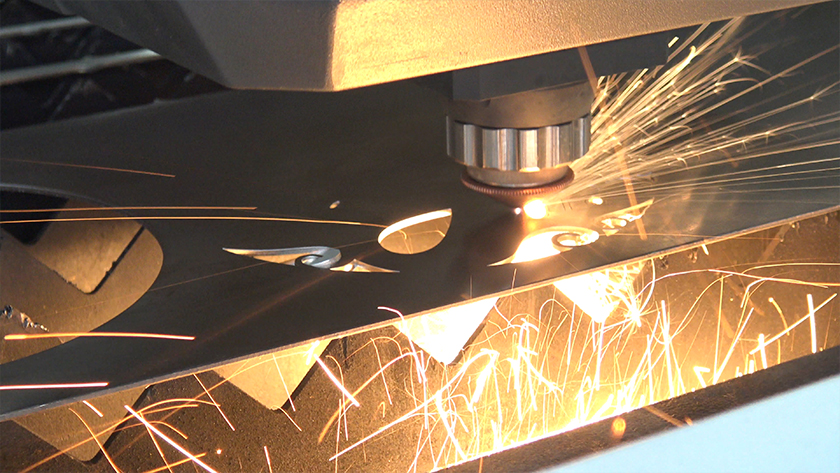

Generally, the factors of affecting the cutting quality mainly include the following aspects: Firstly, the size of the spot after the laser beam is focused; Secondly, the positioning accuracy of the work table;The third is the thickness of the workpiece;The fourth is the workpiece material.The smaller the laser beam spot, the higher the precision of the workbench, the thinner the workpiece thickness, the more conducive to improve the quality of cutting.

07, 2019

by Oree Laser

At present, Laser equipment changes with each passing day. The pace of replacing old equipment with new equipment to become the new mainstream of manufacturing industry is accelerating continuously, such as fiber laser cutting machine replacing CO2 laser cutting machine.

03, 2019

by oreelaser

Due to some improper operation factors, the laser nozzle is blocked or damaged, which affects directly the service life of the cutting machine. This article focuses on the main causes of laser nozzle failure.

03, 2019

by oreelaser

With the rapid development and wide application of laser technology, we can see a wide variety of laser products in our living environments. Not all laser products can be used safely, so how do you know if a laser product is safe?

03, 2019

by oreelaser

Fiber lasers are the core components of the fiber laser cutter and it have a large impact on the cutting performance of laser cutting machines. When choosing a laser cutting machine, what is the module integration method that needs to consider fiber lasers?

03, 2019

by oreelaser

With the increasingly fierce competition in the laser processing industry, how to improve efficiency and reduce costs has become a concern of most laser users.

03, 2019

by OREELASER

In the laser cutting process, we all know the factors affecting the cutting quality performance are including laser beam quality, laser power, cutting speed, work piece thickness. Besides that the nozzle of the cutting head is also an important factor.

02, 2019

by OREELASER

The use of advanced fiber laser cutting machines has improved the quality of domestic elevator manufacturing. Elevator manufacturers are also aware of the need to improve equipment automation and intelligence to respond flexibly to various production tasks and increase production capacity.

02, 2019

by OREELASER

The fiber laser cutting machine adopts a fiber laser generator as the laser source, but the CO2 laser cutting machine generally drives a laser tube by a laser power source to realize the cutting purpose. So what are the advantages of fiber laser cutting machines?

01, 2019

by OREELASER

As more and more industries increase the demand for laser cutting equipment, new challenges are placed on laser cutting equipment. However, there are still some material which the fiber laser cutting machine can’t be suitable for process now. What kind of materials are there?

02, 2019

by oreelaser

Metal laser cutting machine is a high-tech product invented in the era of rapid industrialization. However, when using metal laser cutting machine, many operators will find that metal laser cutting machine occasionally heats up too fast. Then, what are the reasons for the rapid increase in water temperature of metal laser cutting machines?

02, 2019

by oreelaser

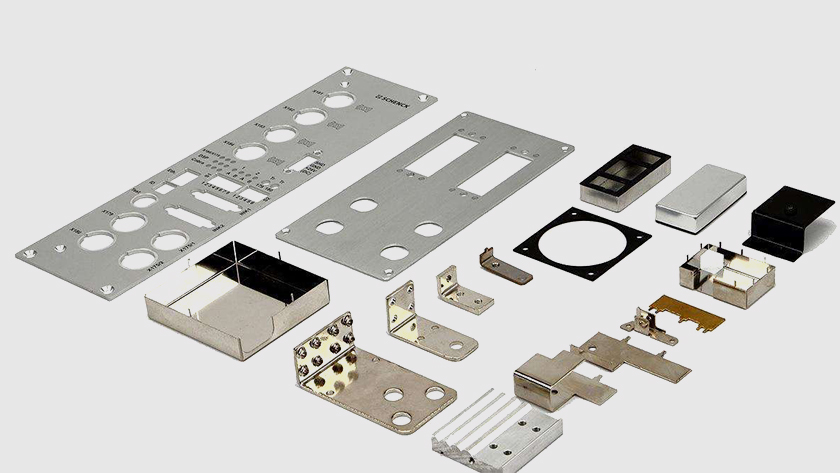

Since the birth of the metal laser cutting machine, the application range has become more and more extensive. Today, I will talk the application of the metal laser cutting machine in the field of stainless steel.

02, 2019

by oreelaser

The development of food machinery manufacturing industry has been on the rise in recent years. With the increasingly severe food safety, the upgrading of equipment has become a big trend. Laser cutting is non-contact, clean and hygienic, suitable for food machinery safety production.

01, 2019

by oreelaser

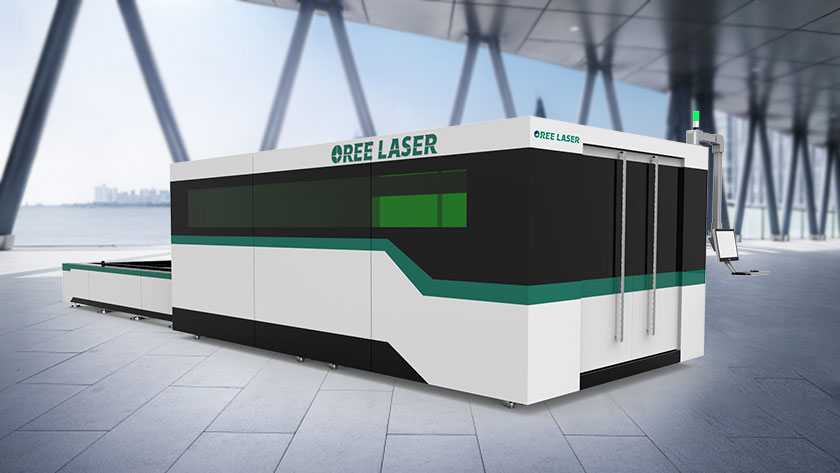

As the leading brand in the laser industry, Oree laser high-power fiber laser cutting machine has refreshed the laser cutting limit in history, redefines the laser industry application, and solves many technical barriers in many industries.

11, 2018

by oree laser

With the rapid development of the sheet metal processing industry, it has created conditions for the wide application of thin plate laser cutting machines. Especially in recent years, we have seen that thin-plate laser cutting machines have become an indispensable driving force for the development of the metal processing industry.

11, 2018

by OreeLaser

The market expansion of thick-plate laser cutting equipment has placed higher demands on the power of lasers, prompting laser manufacturers to continuously develop higher-power lasers. In order to meet this market demand, high-power lasers came into being.

10, 2018

by oreelaser

Due to the different physical characteristics of lasers, CO2 lasers and fiber lasers have different processes. That is to say that both they all have their own strengths and weaknesses, and its own advantages and disadvantages depending on the processing objects.

10, 2018

by Oree Laser

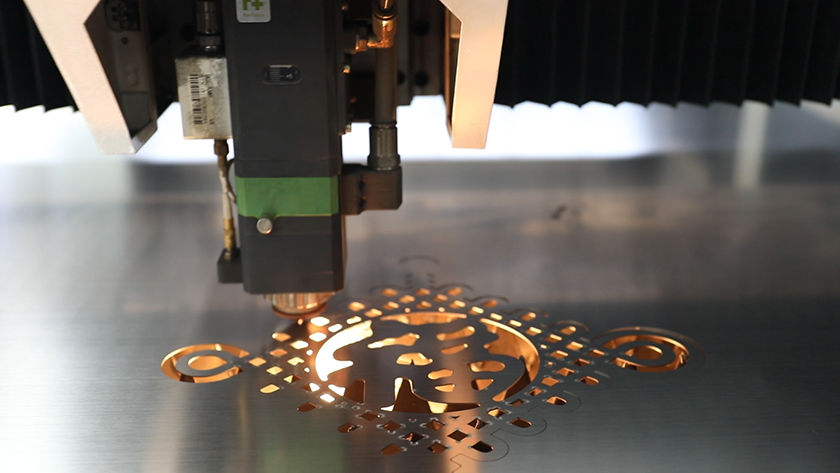

One of the great advantages of laser cutting machines in metal processing is that they offer unparalleled flexibility to machine metal parts of different shapes and sizes without the need for molds. Any creative idea can be laser cut. Machine, fast processing into a finished product.

10, 2018

by oreelaser

Nowadays, the tube laser cutting system is developing towards high flexibility and high automation, and finally it can realize the production mode of different materials and small batches. Therefore, to understand and break through the key technology of tube laser cutting system, system equipment suppliers can have a broader development prospect in the field of metal pipe cutting.

10, 2018

by oreelaser

Compared with other cutting machines, tube laser cutting machines are specialized in cutting metal pipes with a certain thickness. Due to the large demand in the industrial market, pipe laser cutting machines are essential tools to meet diverse market demands

10, 2018

by oree laser

The fiber laser is the core equipment of the fiber laser cutting machine, which has a great impact on the use of the whole machine after its failure. One of the main causes of failure of fiber laser power supplies and modules is the condensation inside the laser. The internal condensation of the fiber laser has a lot to do with the bad operating habits of the fiber laser.

09, 2018

by Ada liu

As we all know that the fiber laser cutting machine is with high power, good cutting precision and high cutting speed. It mainly used in automotive industry, advertising industry, kitchen utensils industry, sheet metal processing, cabinet industry, fitness equipment and other industries.

10, 2018

by Ada.liu

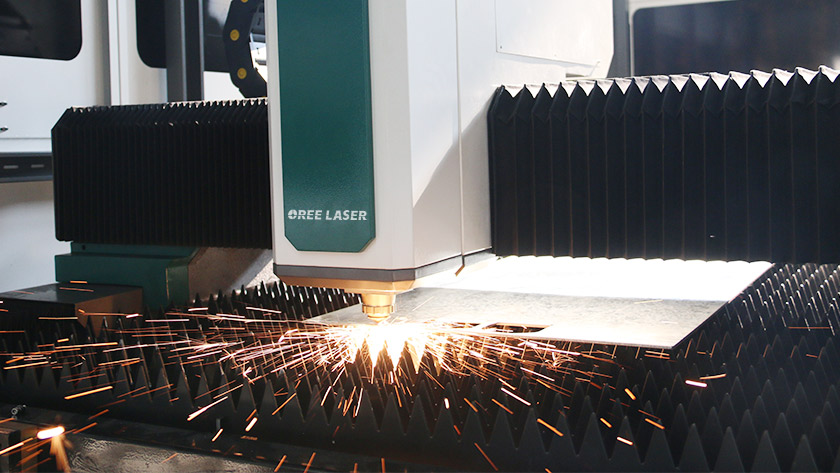

As we all know that there are many factors which affect the cutting quality and cutting efficiency of the fiber laser cutting machine. Oree laser, as a professional laser manufacturer will introduce the most important six core component as a buy guide for you when you want to purchase a fiber laser cutting machine.

MARCH 02, 2019

by oreelaser

At the beginning of 2019, a steady stream of orders made the factory so lively. It is very busy for workers to product, pack and deliver, all which make us have a better harvest in the New Year.

MARCH 11, 2018

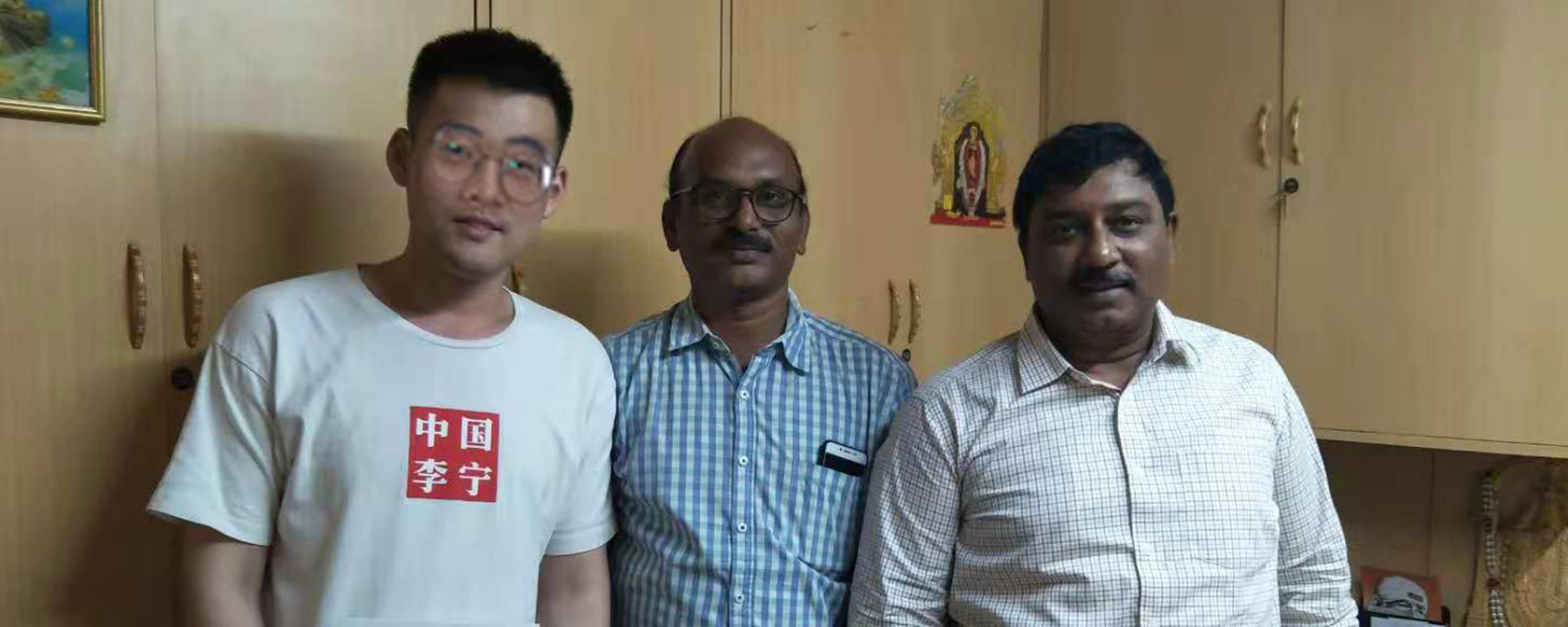

by Oree laser

Recently, Oree laser Overseas Department came to India and visited the old customers. In the cold winter, we brought warmth to our customers, not only sent the care of our entire team, but also brought our professional after-sales and technical support to our customers.

MARCH 10, 2018

by oreelaser

The Canton Fair, the comprehensive international trade event with the best results, is about to be launched. As a professional fiber laser manufacturer, Oree Laser is looking forward to meeting you at the Canton Fair.