11, 2019

by Oree Laser

What is over-burning?

Fiber laser cutting machine generates a large amount of heat when processing the sheet metal. Under normal conditions, the heat generated by the cutting will diffuse along the cutting seam into the processed sheet metal and get sufficient cooling. In the processing of the small hole of the metal laser cutting machine, the outer side of the hole can be sufficiently cooled. The small hole portion inside the single hole is easy to cause over-burning and slag hanging because of the small space where the heat can diffuse. In addition, in the slab cutting, the molten metal accumulated on the surface of the material and the accumulation of heat generated during the perforation may cause the auxiliary airflow to be turbulent and the heat input to be excessive, thereby causing over-burning.

How to avoid over-burning when laser cutting sheet metal?

● Add a cooling point at the corner

When cutting the sharp corner metal sheets, the position when the over-burning is more likely to occur is often at the sharp corners. The over-burning will cut the sharp corners into a circle, then you can add a cooling point in the sharp corner, pause in the sharp corner, blowing air.

Cut sharp corners by over-burning to round corners

No over-burning cutting sharp corners

● Use high power lasers

When cutting carbon steel, a higher power laser can be used. The bright surface cutting technology can effectively avoid over-burning, and this cutting technology can cut out finished products with burr-free, bright cut surface.

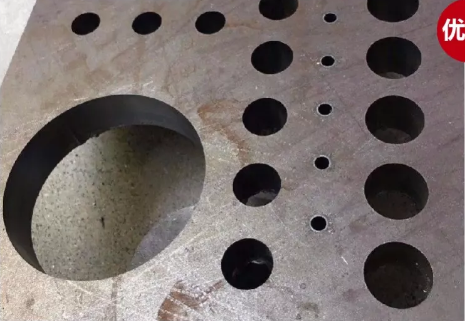

over-burning cutting holes

High power laser bright surface technology cutting holes (no over-burning)

● Nitrogen cutting

In the sheet metal cutting with oxygen as auxiliary gas, nitrogen can be switched to cut. During nitrogen cutting, the material is completely melted by laser energy, and nitrogen is blown out of the slit to avoid the improper chemical reaction. The temperature in the melting point area is relatively low, with the cooling and protection effect of nitrogen, the reaction is stable, even and the cutting quality is high. The section is fine and smooth, the surface roughness is low, and there is no oxide layer.

● Increase air pressure

When using the fiber laser cutting machine to process aluminum and stainless steel, the auxiliary gas used is nitrogen or air, and in the cutting process will not occur burning edge. However, due to the high temperature of the material inside the small hole, the slag hanging phenomenon inside the hole will be more sufficient. In this case, the burr and slag can be reduced by increasing the pressure of the auxiliary gas.

Oree laser cutting machine cuts stainless steel, carbon steel, aluminum four different materials metal plate effect

Professional Laser Cutting Machine Manufacturer - OreeLaser