11, 2019

by Oree Laser

The temperature has plummeted, people have to add clothes, and lasers should also pay attention to antifreeze. Here are a few tips for laser antifreeze. Learn quickly!

Basic principles and methods of antifreeze

There is a “freezing point” in the cooling water. When the cooling water temperature is lower than the “freezing point”, the cooling water solidifies and expands in volume, causing overcurrent components in the laser cooling system, such as water-cooled plates, water separators, etc. To expand and deform, and even burst. For high-power lasers, the core optics are installed on the water-cooled board. And the bursting of the water-cooled plate will directly lead to the laser having to be returned to the factory for maintenance, thereby causing a large economic loss to the user. Therefore, the winter antifreeze measures of the laser must be done.

The following are 3 solutions:

● Keep the water cooler running

In the case that there is no power outage in the local area, the chiller can be kept running, and the low-temperature water and the normal temperature water are both set to about 5℃ (to ensure that the chiller is above the freezing point, and save electric energy.)

● Drain the cooling water inside the machine

The cooling water in the laser and water cooler is emptied after each use.

☞Drainage method

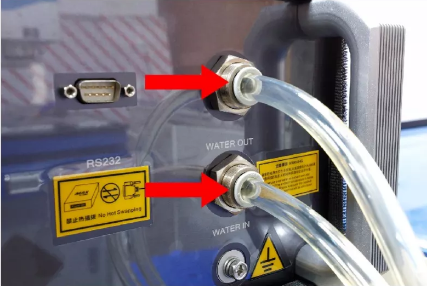

1.Remove the water pipe from the water inlet form the chiller, and then ventilate the water inlet (WATER IN) with compressed gas until the residual water in the chiller is blown out.

▲water chiller drainage diagram

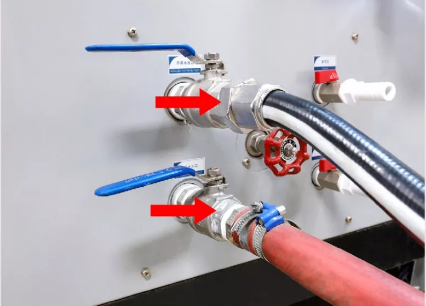

2.The water pipe of the water inlet is removed from the laser, and then the water inlet (WATER IN) is ventilated with compressed gas until the residual water of the water cooling pipe inside the laser is blown out from the water outlet.

▲multimode laser drainage example

3.The water pipe of the water inlet is removed from the laser, and then the water inlet (WATER IN) is ventilated with compressed gas until the residual water in the laser-cooled pipe inside the laser is blown out from the water outlet. Then use a water pipe (or rubber stopper) to plug the water inlet and outlet to prevent dust from entering the water pipe.

▲single-mode laser drainage example

● Replace the cooling water with antifreeze

Antifreeze must be used when the environment is often blacked out and there are no conditions to drain the cooling water every day.

Antifreeze selection

● Please select the appropriate antifreeze based on the local temperature.

The selection of antifreeze is not the lower the freezing point, the better, but according to the local minimum temperature, choose an antifreeze that is slightly lower than the local temperature.

● It is recommended to use professional brand antifreeze

☞Note:

Antifreeze does not completely replace deionized water and is not recommended for long-term use throughout the year. After winter, it is recommended to wash the tubing with deionized or distilled water and return to use deionized or distilled water as a coolant. If the machine is shut down for a long period (such as during the Spring Festival shutdown), it is recommended to drain the cooling water from the equipment and use compressed gas to blow off the residual water in the equipment (including the laser and chiller).

Professional Laser Cutting Machine Manufacturer - OreeLaser