12, 2018

by oreelaser

We have been discussing the cost of fiber laser marking machines: why the price gap is so large; how long the equipment can be used, and so on. These problems are not only the concerns of laser equipment manufacturers, but also the problems customers want to know. The determinants of these problems often have a lot to do with lasers. Oree laser meets your curiosity and takes you to know about the internal structure of the laser.

The structure of the laser of the fiber laser marking machine is the same as that of the fiber laser marking machine. It is modularized and integrated. The inside is not mysterious and full of unknown unreliable dangers. It is undeniable that it is a product of wisdom under highly civilized conditions and belongs to high-tech derivatives. At the same time, its technical threshold is higher than that of fiber laser marking machine, and it has higher requirements for objective conditions of employees, environment and tools. This also increases the curiosity of the laser of the fiber laser marking machine, and many of the practitioners of the fiber laser marking machine have never seen the internal structure of the laser, let alone the customer?

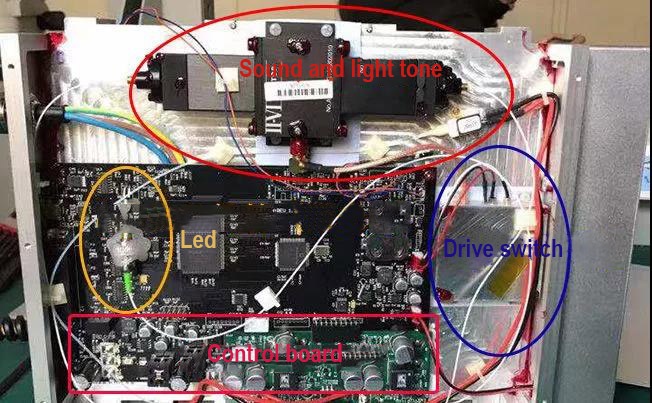

The internal structure of the laser of the fiber laser marking machine is as follows:

The module of the laser includes LED, AOS, Q-light, PCB circuit board, fan, heat-dissipation module, optical fiber, temperature feedback control measurement module, beam expansion module, transmission fiber, etc., there just to satisfy everyone's curiosity. Do not do any technical discussion.

From the module in the above figure, we can understand that even if the power of the laser is attenuated, or if it is damaged for some reason, some of the modules need to be replaced or repaired. In fact, it is the same as the desktop computer we are repairing and assembling. However, no matter how the insurance is over, there are always some maintenance costs, so the customer needs special protection during the use, especially in the harsh environmental conditions, it is necessary to strengthen the protection, such as sand, dust, overheating, etc. Regular maintenance, and the fiber is easy to break, need to be protected during the movement process, especially the hand-held or split-type fiber laser marking machine, need to pay attention.

In the internal structure of the laser of the fiber laser marking machine, each module has its own unique functions, which are integrated to realize the transmission of high-energy beams, and the processing of materials through optical devices such as galvanometers and lenses. In addition, there are some differences in the structure of lasers from different manufacturers, the functions are similar, and the difference in stability is increased, which are also important factors that determines the price, life and stability of fiber laser marking machines.

Professional Laser Cutting Machine Manufacturer - OreeLaser