11, 2020

by Oree Laser

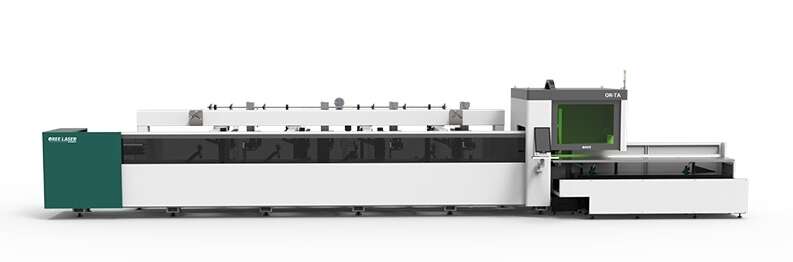

Oree high-speed tube cutting machine TA series is a high-precision tube processing equipment that supports automatic loading and unloading. It has strong scalability and can flexibly deal with various types of pipes, profiles and special-shaped pipe processing in large quantities. With the characteristics of high precision, high efficiency and stability, it is widely used in automatic production lines, fitness equipment and other pipe processing industries. It includes three models: TA6016, TA6020, and TA9020.

Semi-enclosed and extended protective cover for loading area

Adopting European standard design, the feeding area is specially equipped with an extended protective cover to isolate the automatic feeding area from other areas of the site to avoid mutual interference and ensure the safety of the production environment.

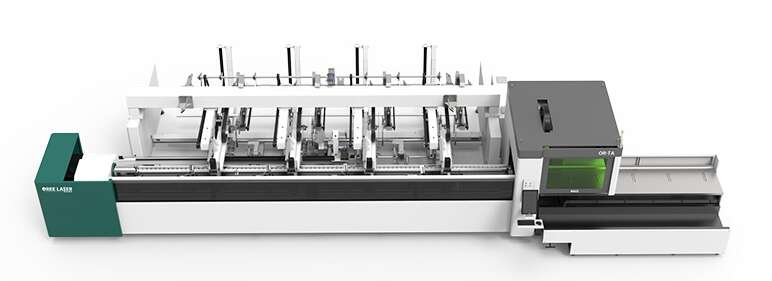

Automatic intelligent high-speed feeding system

·Loading and cutting are carried out simultaneously, reducing non-production time and realizing efficient cutting.

·Imported high-torque servo motor, high precision, high speed, large torque, large inertia, stable and durable performance, ensuring high speed and acceleration performance.

·Single loading weight can reach 5 tons.

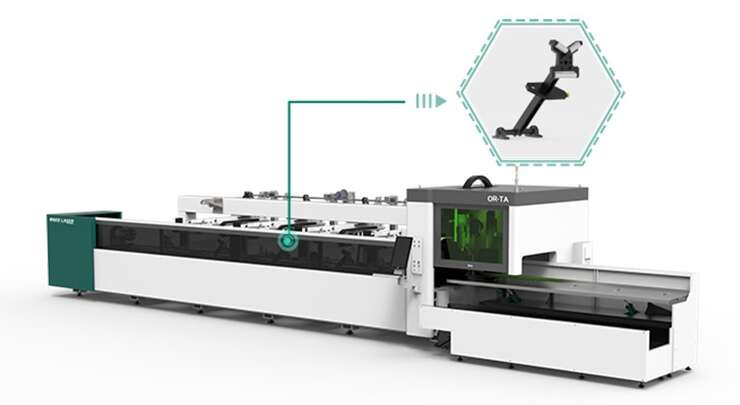

High-precision self-centering pneumatic chuck

·Fully automatic high-precision self-centering pneumatic chuck, adopts precision helical gear transmission, more precise;

·Powerful self-centering function, 3 times the speed of electric chuck, convenient and efficient

·Pneumatic chuck one-button clamping, variable air pressure control clamping force, free control of clamping force, effectively preventing the deformation of thin tube cutting and clamping

·The chuck has no remaining material design, and the remaining length of the material is ≥80mm (Depends on the specific material)

Double-sided follow-up support device

·Double-sided support device

It can reduce processing errors, ensure uniform force on the entire metal pipe, and improve cutting accuracy.

·The chuck and support device are highly synchronized

Real-time feeding to prevent the reduction of cutting accuracy due to pipe distortion.

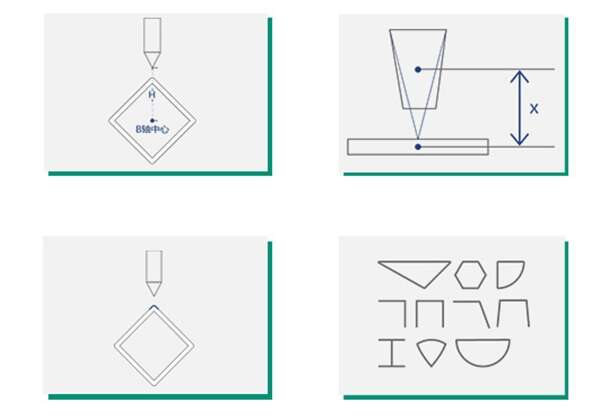

Upgrade the tube cutting bus system

FSCUT5000 pipe cutting bus system supports high-precision and high-efficiency cutting of square pipes, round pipes, racetrack-shaped, elliptical and other stretched pipes, as well as angle steel and channel steel.

·Z-axis follow-up control

·Automatic centering

·Corner craft

·Special-shaped steel cutting

Intelligent pipe jacking software

With the Cypcut tube jacking software TubesT, it can realize drawing processing, co-edge cutting and other process settings and parts drawing functions, which saves time and materials.

· Jacking

· Special coedge

· Drawing processing

· Automatically sorted

Efficient automatic lubrication system

[1] The number and time interval of automatic lubrication can be manually set according to the length of equipment use;

[2] Automatic lubrication for multiple points such as guide rails, sliders, gears, racks, etc., without manual lubrication;

[3] The lubricating waste oil can be recycled and centralized processing.

TA601TA6016 | TA6020 | TA9020 | |

Round tube processing size | φ10mm-φ165mm | φ15mm-φ230mm | φ15mm-φ230mm |

Square tube processing size | 20mm*20mm-115mm*115mm | 15mm*15mm-160mm*160mm | 15mm*15mm-160mm*160mm |

Maximum weight of single pipe | 300kgs | ||

X/Y axis positioning accuracy | ±0.02mm | ||

X/Y axis repositioning accuracy | ±0.03mm | ||

X/Y axis max moving speed | 80m/min | ||

Remaining material length | ≥ 80mm(Depends on the specific material) | ||

Max acceleratio | 0.8G | ||

| Input power | 380V/50-60Hz | ||

Optional laser power | 1000W/1500W/2000W/3000W/4000W/6000W | ||

Professional Laser Cutting Machine Manufacturer - OreeLaser